Knowledge Base - What is a Box-Wall Down Jacket?

May 24, 2022

A Box-wall down jacket is one that utilises 'Box-wall' construction for it's baffles. Baffles are the pockets of space that are created between two layers of fabric which then hold the goose or duck down that is in your jacket. These chambers filled with down are how the jacket keeps you warm. Your body heat warms the air around it through radiating that heat, when you are wearing a down jacket the air that you are warming with your body heat is trapped by the down, creating a layer of warm air around you. The more loft a jacket has, the more air that can be trapped which is why the bigger, puffier down jackets are warmer than more low-profile down jackets.

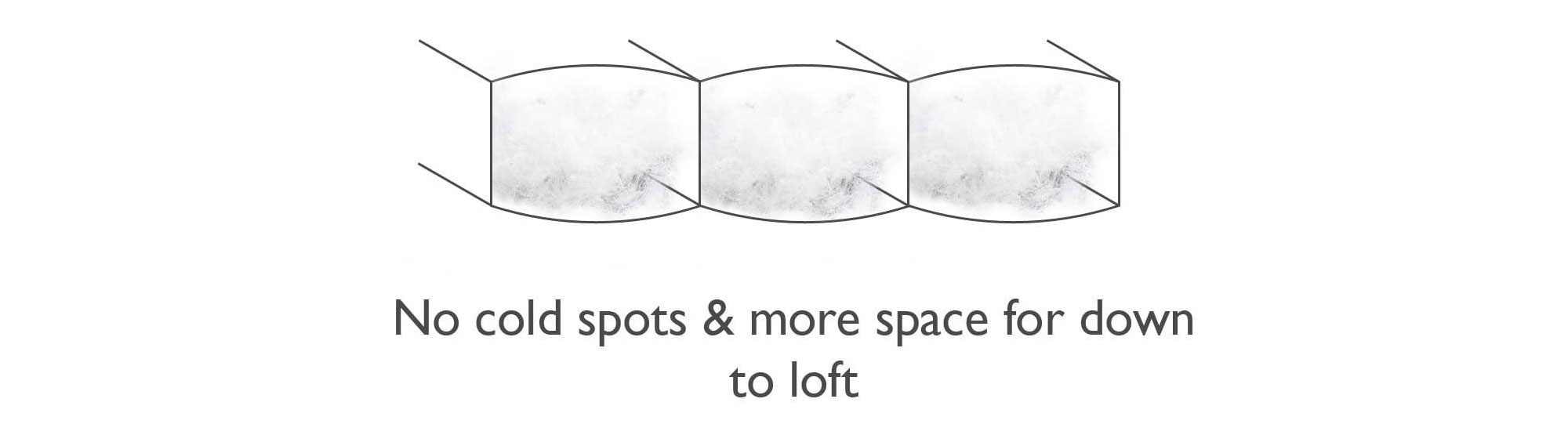

Baffles can be built mainly in two ways 'Box-Wall' or 'Stitch-through', box-wall construction is the warmer of the two as it allows the down to loft more which more effectivley procides warmth, this results in fewer cold spots in the jacket. These horizontal compartments are designed to hold the down in place around the body and maximize the performance of the jacket - jackets using this method are quite often heavier and don't pack down as small as most jackets that use stitch-through construction due to more materials being used.

As you can imagine making fabric 'boxes' for the down rather than sewing through quilt style is a lot more work and is a lot more complicated to make. For this reason the majority of down jackets on the market are 'stitch through' and the few that are 'Box-Wall' are more expensive. The technology is usually reserved for the more demanding products such as high-mountain & expedition gear.

The Alternative: Stitch-Through

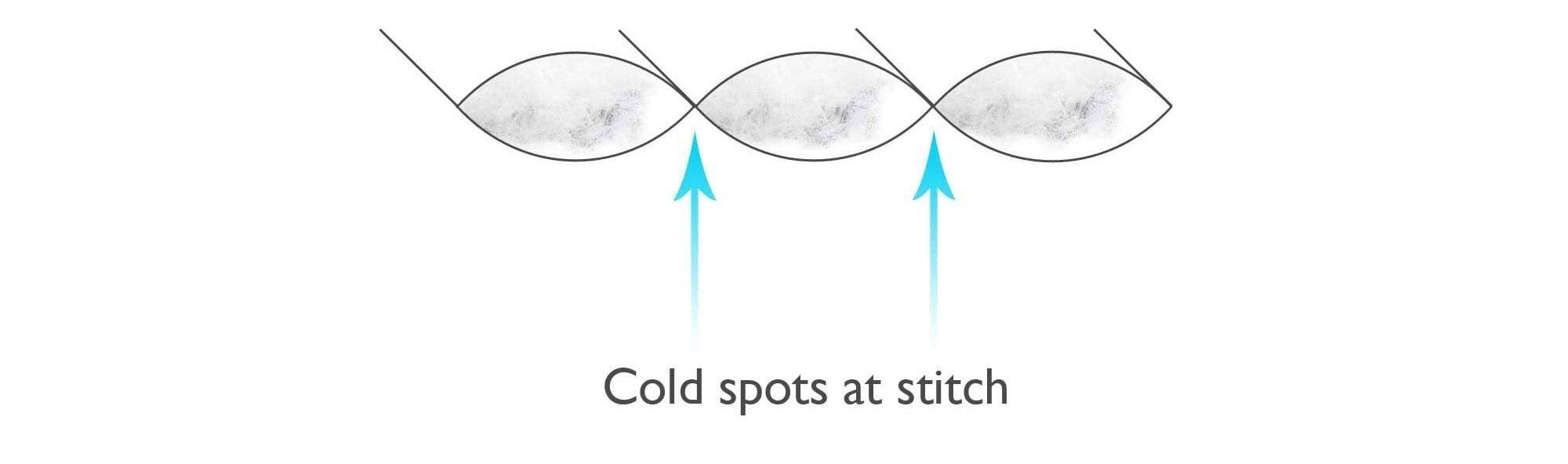

Stitch-through construction is the more common approach as it is easier and less time-consuming to produce for manufacturers; the outer material is stitched directly into the inner lining, separating the down in different baffles. This is less warm than box-wall because the down is pinched at the seams, reducing the optimum loft of the down, at the point of the seam the down cannot loft at all, this creates cold spots.

The benefits of using stitch-through baffles are that this method uses less fabric overall and is lighter than more complicated box baffle construction, it helps keep the price of the down jacket low too.

Stitch-through baffles are most suited to lightweight down jackets that are not designed for high-mountain and polar expedition use. This should be an indication of why you may only see box-wall construction on the very top end of the scale of down jackets.

The Lowdown

So what are the main points that you should consider if you're thinking about getting a box-wall down jacket?

Benefits of Box-Wall

- The down in the jacket will have more space to loft closer to it's potential max fill power

- The box-wall baffle reduces potential cold spot areas on the jacket

- Jackets using box-wall construction will be warmer than jackets using stitch-through construction (if same amount and quality of down is used)

Drawbacks

- Cost: Box-wall construction bumps the price of a jacket up, is it worth the extra for you?

- It adds weight: we know that every gram counts and box-walls add weight to jackets

- Is it necessary? This technology is usually only found on the warmest jackets, you might want to consider a lighter jacket.